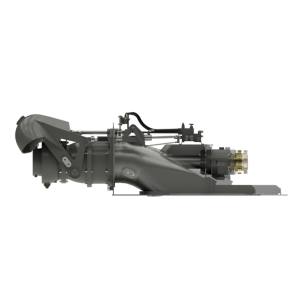

This group of waterjets all utilise an optimised design intake duct, fabricated entirely from hull matching material resulting in an extremely strong and lightweight structure. The installation method provides a high strength, simple and precise integration of the intake duct into all types of hull design and construction.

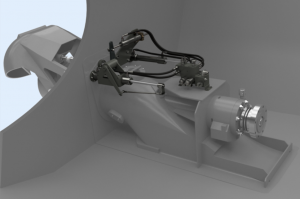

Optima Series waterjets use our latest impeller technology to deliver mixed flow type, high speed performance, within an axial build. This approach together with hydrodynamically advanced intake geometry combines the key benefits of exceptional high-speed performance with superior cavitation margins and excellent efficiency at lower speeds and cruise conditions.

Consistent with the rest of our waterjets, no special tools are required for installation or maintenance of these models. Designed and built with modular construction, using the best of class materials with special dual coat paint system and optimal anode placement providing exceptional reliability, extended component life and simple maintenance – hence the lowest cost of ownership ongoing.

Superior Preformance

Light fabricated intake duct grants significant weight reduction for the waterjet, and consequently the finished build. Together with the optimised geometry of the intake tunnel and our advanced high-performing pump design, this translates into superior efficiency compare to similar size equipment on offer by the competition.

Customised Designs

Tailored Waterjets – Special high speed intake, accommodating hull contour or varying the shaft height ans supplying narrow reverse bucket to suit twin installation on confined demi hulls are among customisation possible with Optima Series.

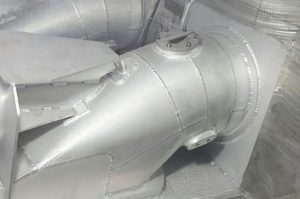

Best of Class Material

Stainless Steel Pump Assembly – For ultimate durability against corrosion, erosion and wear and tear, the impeller, impeller casing and discharge nozzle are all made of stainless steel, which also makes them cost-effectively repairable in case of normal wear to damage.

Easy Installation

Ready to Install – The intake duct of these waterjets is supplied as a complete fully machined part ready to install with no need for sophisticated alignment tools. The benefit to the ship builder is obvious; with no requirement for re-work or in-vessel machining and finishing. For fiberglass hulls and using our Integrated Waterjet (IWJ) technology, the intake is directly moulded into the hull.

Integral To Hull

The intake duct in Optima Series is manufactured from hull matching materials to ensure complete compatibility and to eliminate the need for any dissimilar material isolation. Furthermore, hull integrity is preserved through the fully welded installation with no internal flanges to seal and maintain in the transom or bottom of the boat. For fiberglass hulls an absolute assimilation of intake duct into the hull is achieved by Integrated Waterjet (IWJ) variant

Fully Inboard Hydraulics

Entire hydraulic module including the revere and steering cylinders and associated valves, pipes and hoses and fittings are all fully inboard and protected from corrosion and marine growth. This also makes them readily accessible for maintenance or repair without the need to dock the vessel.

Model Range

No matter how big or small is your vessel, we have a waterjet model in our comprehensive range to suit. Understanding the application is a key factor in choosing the right waterjet; we work closely with you to appraise the optimum size waterjet and the configuration that best meets your budget requirements without compromising vessel capacity to sustainability perform its designated role.

Currently, there are eight models within the Optima family suiting engine power up to 5000 horsepower.

Please contact us and our engineering application dedicated team will assist you with the jet selection and all your technical inquiries.

Note

- Max Rec. Power for standard model (subject to application eng. review)

- Includes Std. Reverse Control System – Excludes Entrained Water

- Booster (B), Direct Thrust (DT) waterjet or Integrated Waterjet (IWJ)

- Typical only – not to be used for construction purposes

- Standard stated – custom shaft angle available